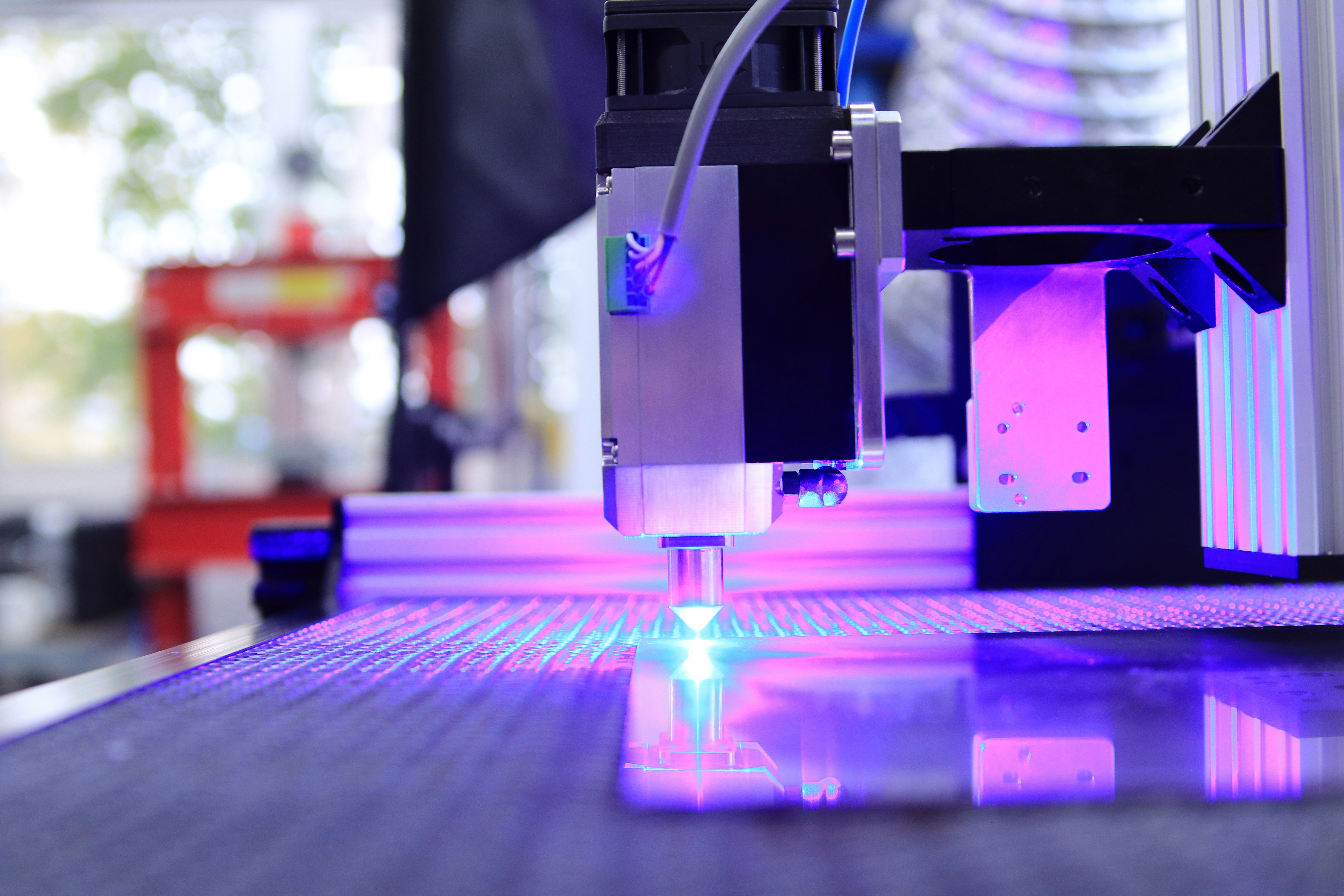

Green Laser Welding: Revolutionizing Copper Processing

Learn how our new green laser technology achieves unprecedented weld quality in copper and other highly reflective materials.

Dr. Anna Lindström, R&D Director

Mestec AS

The challenge of welding highly reflective materials like copper and gold has long been one of the most demanding applications in industrial laser processing. Today, we’re excited to share how our new green laser welding technology is solving this challenge with remarkable results.

The Problem with Traditional Laser Welding

Standard infrared (IR) fiber lasers operating at 1070nm wavelength face significant challenges when processing copper:

- High reflectivity (up to 98%) at IR wavelengths

- Inconsistent energy absorption leading to unstable weld pools

- Risk of back-reflection damaging the laser source

- Poor weld quality and repeatability

These limitations have historically made copper welding a slow, expensive process requiring specialized techniques or alternative joining methods.

The Green Laser Advantage

Our new green laser systems operate at 515nm wavelength, where copper’s absorption rate is dramatically higher:

| Material | IR Absorption (1070nm) | Green Absorption (515nm) |

|---|---|---|

| Copper | ~5% | ~40% |

| Gold | ~2% | ~35% |

| Brass | ~10% | ~45% |

This 8x improvement in energy absorption translates directly to:

Better Weld Quality

- Consistent keyhole formation

- Minimal spatter and porosity

- Smooth, clean weld seams

Higher Processing Speeds

- Up to 5x faster than IR lasers on copper

- Reduced cycle times

- Higher throughput

Lower Operating Costs

- Less power required for equivalent results

- Reduced post-processing and cleanup

- Longer consumable life

Applications

Our green laser welding systems are already proving their value in several industries:

Electric Vehicle Manufacturing

Battery cell connections require perfect welds between copper busbars and aluminum housings. Our green laser systems achieve:

- Zero-defect welding at production speeds

- Minimal heat input protecting sensitive cells

- Mixed-material joining capabilities

Electronics Manufacturing

From smartphone components to data center equipment, precision copper welding enables:

- Smaller, more efficient heat sinks

- Improved electrical connections

- Higher component density

Renewable Energy

Solar panel and wind turbine manufacturing benefits from:

- Reliable copper interconnects

- Automated high-volume production

- Consistent long-term performance

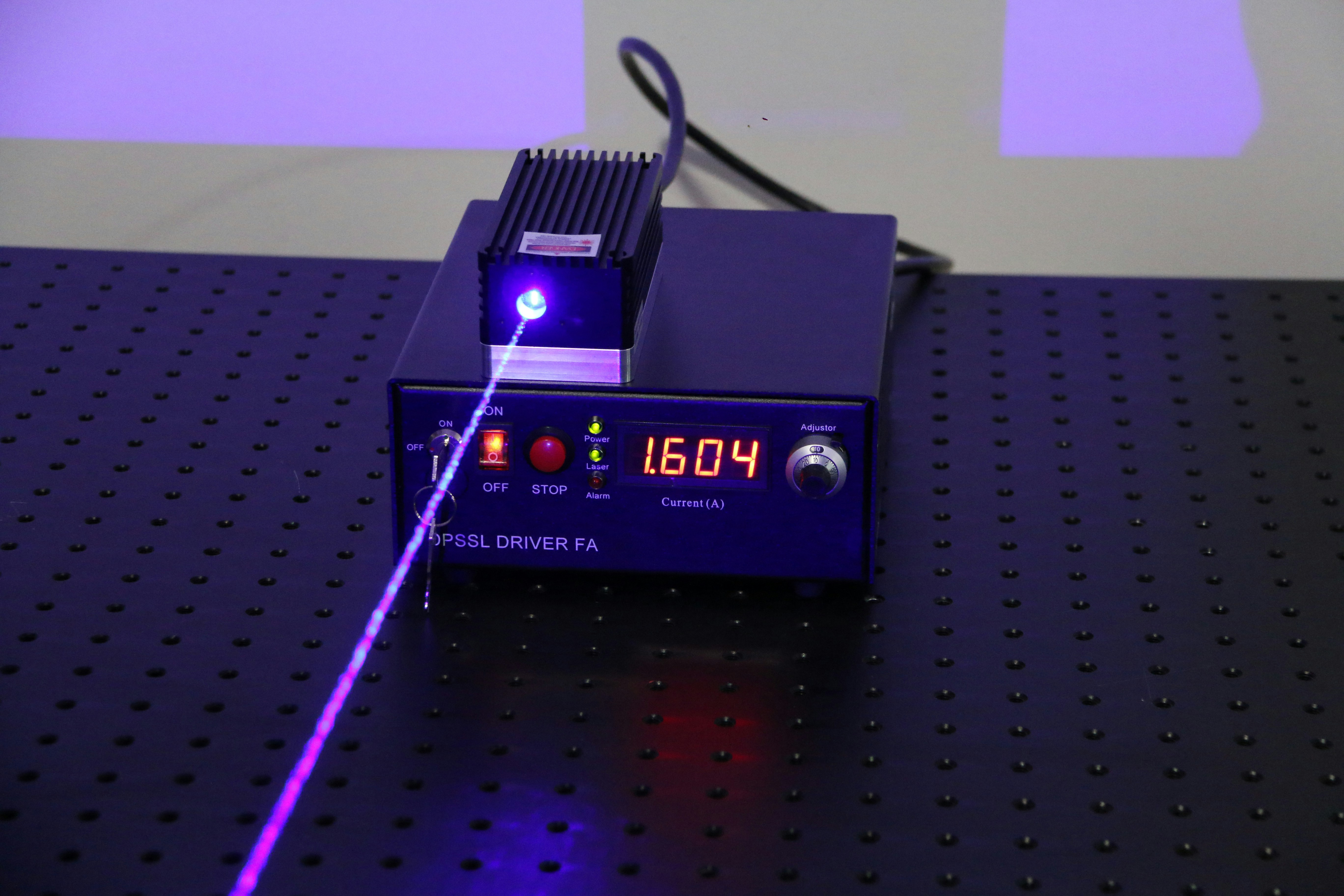

Technical Specifications

Our GreenWeld 2000 system offers:

| Parameter | Specification |

|---|---|

| Wavelength | 515nm |

| Average Power | 2,000W |

| Pulse Duration | 20μs - CW |

| Beam Quality | M² < 1.3 |

| Spot Size | 50-200μm adjustable |

See the Difference

We’ve prepared a series of comparison samples demonstrating the quality difference between IR and green laser welding on various copper alloys. Contact us to receive a sample kit or schedule a visit to our application lab.

Research Partnership

Mestec AS is actively collaborating with leading universities and research institutions to further advance green laser technology. We’re particularly focused on:

- Multi-wavelength hybrid processing

- Real-time process monitoring with AI

- Novel beam shaping techniques

Interested in exploring green laser welding for your application? Contact our applications engineering team at [email protected]